Articles

Leaders of Global Nuclear Industry to meet at World Atomic Week in Moscow

First concrete poured at unit 4 at Leningrad NPP-2

National flag of Russian Federation hoisted on Yakutia nuclear icebreaker

Reactor pressure vessel of Xudapu NPP Unit 4 has been installed in design position

China offers the world a solution through nuclear technology applications

Press Releases

Rosatom Mechanical Engineers Assembled Reactor Vessel for Unit 1 of El Dabaa NPP (Egypt)

Four Employees of the Rosatom Engineering Divisions Awarded by the RF President

Leaders of Global Nuclear Industry to meet at World Atomic Week in Moscow

Corrosion of Alloy 600 - comment of our reader

AtomInfo.Ru publishes one of our readers' response to article of Vladimir Rychin Davis-Besse NPP - mistake in DNA. Surname of author is known to us, however, by his request we left only his name. Text of the letter is published with small editorial corrections.

Mistakes correction

First of all, I'd like to pay attention to annoying errors, which can ruin a very interesting article concerning very important theme.

There are two names of corrosion in English documents, which affects elements of Alloy 600: PWSCC (primary water stress corrosion cracking) or boric acid corrosion. Boron acid is always in primary water of pressurized water reactors, but it doesn't go into water "due to leakage", as may be understood from the article.

Corrosion - but not "erosion', as Vladimir Rychin writes , of elements of Alloy 600 is known among Western nuclear specialists long ago, at least much earlier than incident at Davis-Besse NPP. The report of NRC issued in 2005 (NUREG-1823) states that the first similar incident was registered at the third unit of San Onofre NPP with PWR-1000 reactor in California. Here I&C nozzle at pressurizer is subject to corrosion.

In 1987 nozzles of the same pressurizer "leaked" at unit with PWR reactor in Arkansas. In 1989 there was the first information of PWSCC corrosion at French units. Two years after the first incidents of corrosion damages of control rod nozzles on reactor vessel heads of Western pressurized water reactors were detected. Nowadays "leakages" of measuring detectors in reactor bottom and appearance of cracks in butt weld are observed. Firstly this problem arose in 1971 with "leakages" in steam generators.

All these and other incidents are well documented and collected in the report NUREG-1823 above-mentioned or in another known document MRP-111 (Materials Reliability Program Resistance to Primary Water Stress Corrosion Cracking of Alloys 690, 52, and 152 in Pressurized Water Reactors).

As you see, nobody never considered the information of problems with Alloy 600 as security information. USA laws don't allow to do it. But Vladimir Rychin is absolutely right that all corresponding publications are mainly in restricted specialized professional press, not publishing in popular newspapers and magazines for mass audience. Western companies try to keep their image of designers, manufacturers and proprietors of the safest nuclear equipment in the world.

Let's go back to incident at Davis-Besse NPP. The point is that corrosion destructed CPS drive sleeve. Then corrosion of carbon steel reactor vessel head was started. Material of reactor vessel head is not resistant to PWSCC, as a rule, and in order to prevent this corrosion, sleeves were designed in the projects. Just this sleeve was destructed at American NPP.

I'd like to pay attention to that reactor vessel heads are subject to protection against corrosion in our Russian VVER-reactors too. But as experience of operation showed, our domestic sleeves were designed more successfully than their Western, in the first place American co-brothers. When choosing materials for Russian/Soviet sleeves, alarming experimental information about instability of nickel alloys to PWSCC had been taken into account, which were excluded from consideration by American designers as "unreliable".

What was the next step after destruction of the sleeve? The lower part of reactor vessel head is protected by stainless steel facing (but not "cladding" as Vladimir Rychin writes). Just this facing rescued the Americans from large nuclear catastrophe. By the way, radioactive water would penetrate not to CPS drives, but to reactor room.

Usage of Alloy 600 everywhere in Western projects

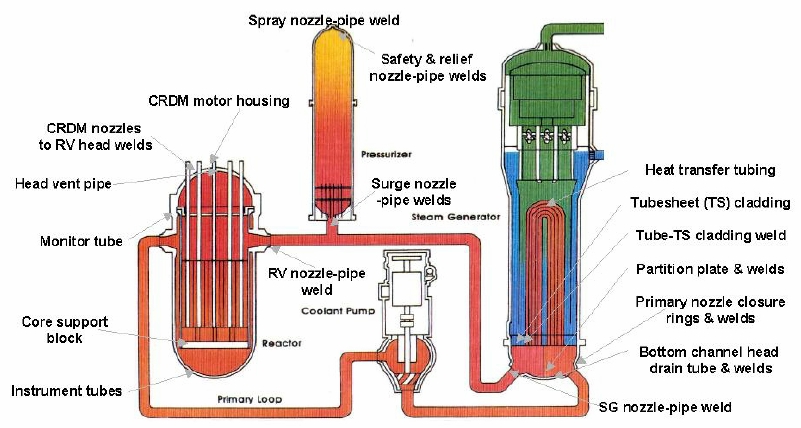

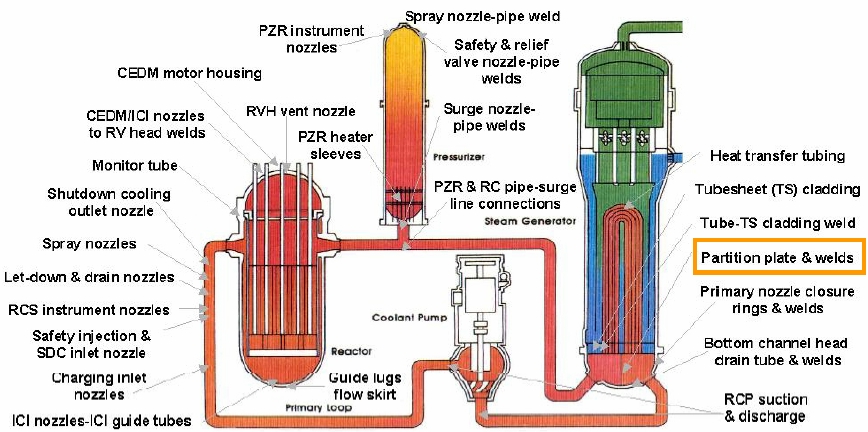

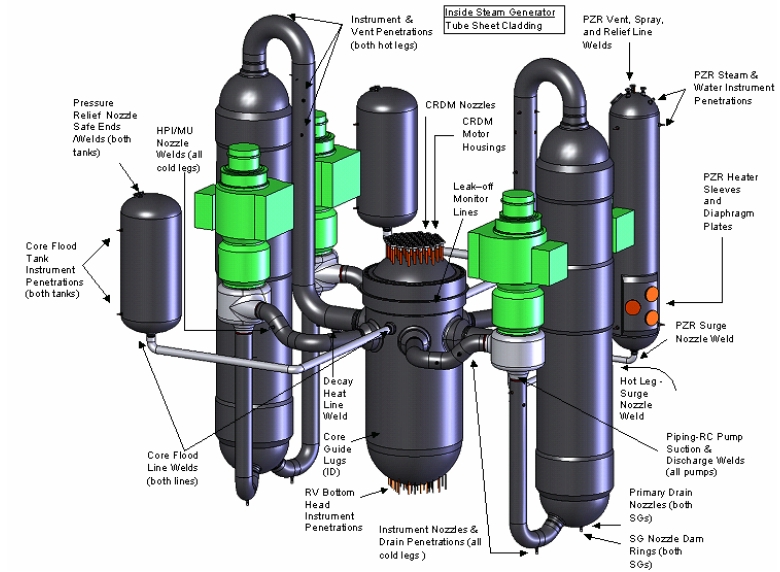

It is very important for anybody who will try to study out problem of Alloy 600, that the main difficulty is connected with that Western designers too often used this material in various elements of unit. In order to make sure of unusually wide application of this alloy, you should look at the layouts of Western reactor projects.

Layout of PWR reactor installation designed by Westinghouse (elements using Alloy 600 are marked in red) - click on mouse button to open in new window.

Layout of PWR reactor installation designed by Combustion Engineering (elements using Alloy 600 are marked in red) - click on mouse button to open in new window.

Layout of PWR reactor installation designed by Babcock & Wilcox (elements using Alloy 600 are marked in red) - click on mouse button to open in new window.

Alloy 600 is used in all nozzles in most Western NPPs, which provide the introduction of measuring detectors, drives, heaters and some mediums in reservoirs and pipe-lines. American designers used elements of this alloy in places of joint of pipelines and nozzles of different material reservoirs. These adapters in English literature are called safe-end, but ironically "safe ends" or safe elements proved sources of real danger in Western projects.

In addition, we shouldn't forget that not only elements of Alloy 600, but welding materials developed on its basis: Alloy 82 and Alloy 182 are corroded.

Problem consideration not only by money

Certainly, problem consideration should take into account market economy. Many people discussing the consequences of corrosion of equipment for NPP, prefer to remember only money losses. Unfortunately AtomInfo.Ru didn't also avoid this mistake. We say about NPP and here we have to pay for all unexpected actions by additional exposure doses for workers.

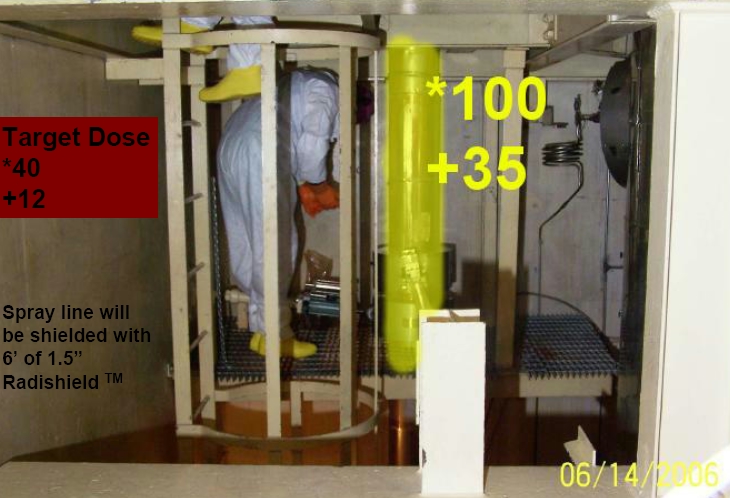

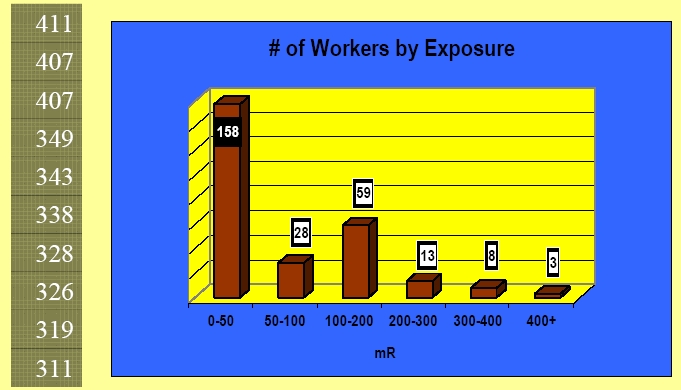

Photo below shows under which complicated conditions the workers of Oconee NPP in South Carolina had to replace equipment and carried out other work within the program for Alloy 600 corrosion control. Total 269 workers got additional doses during fulfillment of this work, 83 workers getting doses of 0,1 - 0,4 rem. These values seem to be not so large, but nobody has canceled ALARA principle yet. The workers had to carry out work at Oconee NPP under conditions, when radiation background was 600 mR/h in some cases, and the risk of overirradiation of workers was too large.

Work on replacing equipment using Alloy 600 at Oconee NPP in USA

Personnel doses obtained during work on replacing equipment using Alloy 600 at Oconee NPP in USA. Graph gives dose ranges plotted on X-axis in mR (mrem), number of workers irradiated within the indicated range plotted on Y-axis. List of ten highest individual doses fixed during replacing equipment is on the left of the graph. Click on mouse button to open in new window.

Instead of conclusion

Finally, I'd like to write several words about what many people often forget, when discussing problem of Alloy 600. How much we could talk about the description of certain problems and series of actions resulted to these problems, how much we could analyze certain and general measures for restriction and prevention - but there is the only notion of this situation discrediting reputation of nuclear power. American designers of PWR reactors, who had chosen Alloy 600 as one of the main structural material, made a critical mistake - mistake in choosing material.

Despite all claims of technical character I fully agree with this main conclusion of Vladimir Rychin.

SOURCE: Eugene, AtomInfo.Ru

DATE: September 09, 2007