Davis-Besse NPP reactor vessel head, photo dated April 2000.

The safest reactors in the world can be shut down due to their increased danger. Independent experts, who investigated insurance accident at "Davis Besse" NPP, have drawn a conclusion of expediency to shut down all 69 units with reactors PWR in USA. US NRC doesn't control its anger. In American nuclear power a scandal is raising comparable by scale with consequences of accident at TMI-2.

Negligence of personnel

American Davis Besse NPP with one reactor PWR-900 in Ohio was shut down not as scheduled due to intensive blocking of filters by boron on February 16, 2002. Careful examination showed that NPP was very close to catastrophe.

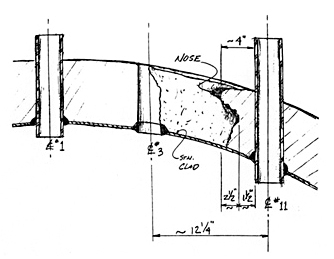

NPP personnel detected "essential wear of the main material in the area adjoining to pipes of control rods", exactly, formation of cavity on the internal side of reactor vessel head with dimension of 18?15?13 cm. The last barrier on the way of water to Control and Scram System (CSS) rods drives was only a stainless steel plate with thickness of 9 mm. Erosion of reactor cover became possible due to corrosion processes caused by the leakage of boron acid from reactor emergency cooling system (RECS). A few weeks were left before mortal stroke of water with pressure higher than 150 atm/cm2 on Control and Scram System of the reactor. It is not surprising that almost all the information about this incident was confidential, and only brief reports had been sent to addresses of international organizations.

"It was not easy to know the details of this carefully suppressed but scandalous incident. Regarding to inquiry to IAEA, IAEA answered that agency didn't considered this incident at its seminars", - Ukrainian newspaper "Zerkalo nedeli" (Week mirror) wrote. However everything becomes known sooner or later. The owner of NPP Davis-Besse shut down, "FirstEnergy Corp." company wished to get insurance compensations for losses and independent expert organizations had been involved in investigation.

Owner's Greed

By now losses of "FirstEnergy Corp." at the expense of payment for repair work and loss of profit due to Davis-Besse NPP shut down exceed USA $600 million. This sum doesn't include paid-up penalty in amount of USA $28 million, which became a record in American nuclear power history. It is not surprising that administration of the company tried to cover losses partially by insurance company "Nuclear Electric Insurance Limited".

Insurers rejected to pay of their own free will big amount of money for the damage caused by personnel negligence. The dispute of incident at Davis-Besse NPP was referred to arbitration. Practically simultaneously in court of Toledo legal proceedings against three workers of "FirstEnergy" company had been initiated on a charge of giving false information to USA governmental bodies.

In autumn of 2001 NRC, USA nuclear regulating body, had the opinion that Davis-Besse NPP is under a threat. However, engineers Andrew Siemaszko, David Geisen and subcontractor Rodney N. Cook, who had been interviewed by NRC inspectors, preferred to hide a true information about the situation at Davis-Besse, and operation of Davis-Besse NPP had been continued again. Lie under oath will cost for engineers maximum - 5 years of imprison and USA $ 250 thousand penalty for everybody.

But as it is known, sheriff doesn't care problems of Indians. Having left its former workers to the mercy of fate, as if they lied NRC by their own initiative, "FirstEnergy" concentrated on its own financial circumstances.

Insurance company reasoned its rejection of compensation payment by conclusions from the report presented to NRC on April 18, 2002. This report stated that during many years there was an undetected small leakage at Davis-Besse NPP, which allowed to contact boron acid with material of reactor vessel. Drop by drop, boron corroded steel with the connivance of personnel.

To deprive insurers of trump card, FirstEnergy paid the services of Exponent Inc.'s experts, the third company. Their conclusions were like a burst of a bomb.

Designer's mistake

The report presented by FirstEnergy to Arbitration and Insurance Company said the following: "Till October or November, 2001 no leakage of boron acid had been observed at Davis-Besse NPP, only after this date a process of leakage and corrosion began, violently developed only during 18 weeks up to its detection in February 2002.

This report caused tremendous reaction of NRC. NRC sent to FirstEnergy administration a resolute letter with requirement to explain why this too sensational document had not been presented to NRC and NRC had to know about it through somebody else? We are not guilty, - Joe Hagan, President of FirstEnergy, explained, - We just wanted to receive our insurance compensation at the amount of USA $ 200 million and only for these purposes we ordered independent investigation of incident causes.

If experts admit the truth of new conclusions and Arbitration's judgement is for FirstEnergy, in this case NRC have to recognize - techniques, procedures and inspection intervals of reactor vessel head and CSS drives at PWR reactors are inadequate to reality and able to miss evolution of large beyond design accident.

Thus, the case about incident at Davis-Besse NPP came to a new level. NRC has already received an official petition from ecological organization "Union of Concerned Scientists" with demand to carry out federal investigation immediately. If the conclusions of FirstEnergy's experts are confirmed, all units with PWR reactors in USA should be shut down up to the moment, until new techniques for controlling CSS drives and reactor vessel head will be developed. It is clear that numerous PWR technology users have to start thinking seriously.

But what or who became guilty of the biggest scandal in USA nuclear branch since TMI-2 accident? All American departments don't answer this question. Only careful analysis of AP-1000 reactor project documentation appeared allows to know the truth.

After incident at Davis- Besse NPP, material 1600MA was removed urgently from the AP-1000 reactor project. American designers actually admitted by this fact - there was an internal critical mistake in PWR reactor technology. In other words - a mistake in reactor DNA.

Here comparison with DNA is not accidental. Following USA, 1600 MA was implemented practically in all PWR projects - similar reactors in the world, except Russia. If unreliable material can be replaced in new light water reactors, unexpected catastrophe at operating NPPs can be prevented only by organizational measures such as careful and repeated inspections.

About seriousness of mistake one can judge on panic behavior of AP-1000 designers. A replacement of 1600MA material is suggested in all elements of new unit of "almost the third generation". First of all it proves that the designer is not sure in reliability of own project.

And lastly, one small, but very specific observation. 1690TT material is called as one of candidates for replacing 1600MA material, which had been discredited. But alternative to I690TT material will be material suspiciously known to many Russian nuclear specialists, it is stainless steel SS316L.

For those, who understand, it is steel, close by its composition to steels, successfully and old-used in Russian VVER reactors.

SOURCE: Vladimir Rychin, AtomInfo.Ru

DATE: September 08, 2007