Lead-bismuth fast neutron technologies in Russia are close to the demonstration. According to the declaration of the director of the energetic machine building department of the "Russian machines" company Vladimir Petrochenko, the first NPP with SVBR-100 reactor can be built in Obninsk in 2015.

But Russian SVBR has foreign rivals. One of them can become Japanese lead-bismuth reactor that is using the CANDLE burnup conception.

CANDLE burnup conception

Reactors of high capacity, as it is well known, can be placed only in the regions with high energetic demands or/and developed nets. For the bigger part of countries such monsters as EPR-1600 or APWR-1700 can be elementary useless - countries of the third world won't be able to consume the produced amounts of electricity.

Besides, developing countries would prefer minimizing possible efforts on behalf of nuclear reactors. Ideally, facilities that don't demand or demand next to nothing servicing during the operation that would be brought to the site by the deliverers, assembled and after the campaign would be returned back to the country of manufacturer would suit them.

A possibility of creating lead-bismuth reactors that use CANDLE burnup conception is researched In Technological Institute of Tokyo under the leadership of Hiroshi Sekimoto. CANDLE is a Constant Axial shape of Neutron flux, nuclide number densities and power shape During Life of Energy producing reactor.

CANDLE conception provides that forms of distribution of isotope concentrations, neutron fluxes and power shape are constant during the exploitation of the reactor, and they are shifting with the constant speed in axial direction. Exceeding reactivity value doesn't change during the campaign, and it means that at CANDLE reactors there is no need to take care of its compensation during the burnup process.

CANDLE active zone will be actually divided on three subzones by their height:

Fuel should be loaded only once be the launch of the first reactor by the CANDLE system, and fuel (enriched uranium or plutonium) will be needed only by creating of the burning zone by the first loading. Speaking about fresh fuel zone, it will contain natural or depleted uranium or thorium.

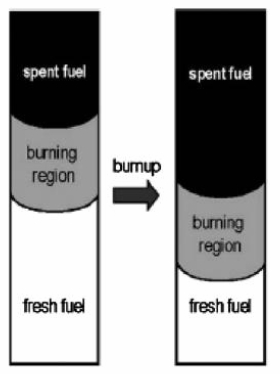

During the exploitation of the reactor, nucleus of the fissile materials in the burning zone will be consumed and in the fresh fuel zone, on the contrary - accumulated. That will cause slow burning zone shift in the axial direction, as it is shown on the Figure 1. After the exploitation of the first reactor burning zone of it can be used to load the second reactor.

Fig.1. Schematic sketch of the "shifts" of subzones by the altitude of the active zone during the burnup according to the CANDLE conception.

As one of the declared advantages of the CANDLE conception Japanese specialists name a super deep burnup in the open nuclear fuel cycle - up to 40%. By such a high efficiency coefficient using of natural uranium, spent fuel proceeding and closing of the nuclear cycle can be not so advisable. This will eliminate one of the potential threats to the non-proliferation system.

Earlier CANDLE conception was elaborated for the big fast and heat reactors, though last time Japanese specialists pay a lot of attention to the lead-bismuth reactors of small capacity. It happened to be not so easy to realize CANDLE strategy in such circumstances, first of all because of the big radial neutron leakage. However excellent characteristics of lead-bismuth have played an important role here, precisely, that fact that this material is a magnificent reflector.

Lead-bismuth reactor from Japan

Main characteristics of the lead-bismuth fast reactor operating by the CANDLE conception are in the Table 1.

Table 1. Main characteristics of the Japanese lead-bismuth reactor.

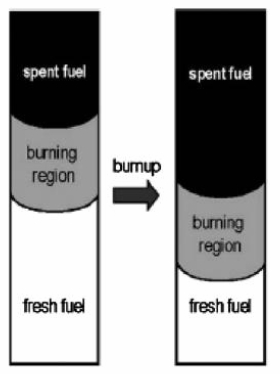

Fuel element of the Japanese lead-bismuth reactor is chosen of "tube in the case" - type, which allows increasing of the volume of the fuel share in the active zone for the more effective use of neutrons (Fig.2). At the same time, specific capacity of the Japanese reactor is not big because of the thermo hydraulic demands.

Fig.2. Fuel element of the lead-bismuth reactor.

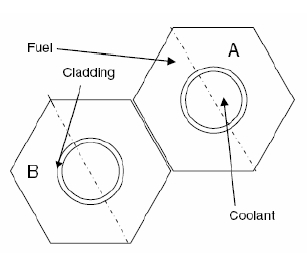

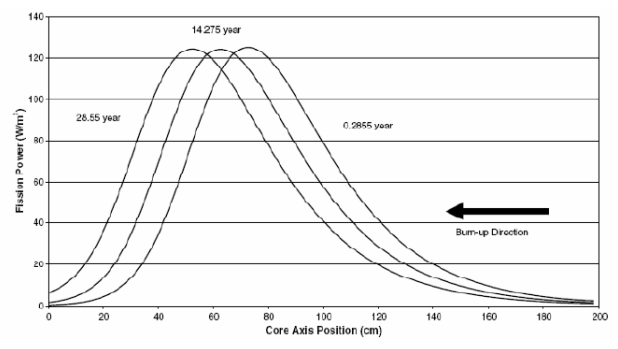

Neutronics and thermo-hydraulic calculations, implemented at TIT, show, that it is possible to create a lead-bismuth reactor that is working by the CANDLE burnup conception. Pic.3 illustrates a smooth shift of the energy producing profile by the altitude of the active zone during the campaign.

Provided effective multiplication factor change will be not more than 0.002 during 30 years of exploitation. So its construction won't demand complex compensation systems for the change of reactivity and burnup. Incidents of the UTOP-type with the spontaneous control rods extraction are excluded. At TIT they think that lead-bismuth reactor that is working in the CANDLE burnup conception is one of the perspective reactors of the fouth generation.

Fig.3. Shift of the axual power-flux in the center of the active zone during the cycle.

Comments of the expert

At the request of AtomInfo.Ru web-edition Russian specialists that is working over the the iqual problem in Russia, commented on the project of the lead-bismuth reactor, that uses CANDLE burnup conception. Considering an unofficial character of the commentary we have to publish his answer on the terms of anonimaty.

Undoubtedly CANDLE is a nice physical idea where neutron-physical processes are elaborated very profoundly. High professional level of the professor's Sekimoto and TIT team in this area is well-known.

I have to add, that the conception, proposed by Japanese specialists is not completely elaborated and now it is rather early to judge about the possibility of putting it into practice.

What attracts attention at once? Conception doesn't develop a so-called starting area, it means the mode of reaching reactors equilibrium position. On the first stage of exploitation active zone should be loaded by enriced uranium or plutonium. And a reactivity reserve will be more than a dollar with all the ensuing consequences.

There is a second problem to be mentioned. To make the reactor operate as long as it is provided by the CANDLE concept (campaign should be not less than 30 years), a long active zone will be needed (Japanese project has a length of 200 cm and radius of 100 cm). But it is not so good for the coolant circulation.

Let us also remember that lead-bismuth is a heavy coolant, which demands certain losses for pumping. Long active zone will cause an increased hydraulic resistance and will provoce a growth of the pumps capacity.

The project provides using of uranium nitride enreached by 15N to get good neutron-physical characteristics. But today there is no any industry capable of producing such a fuel. So we can't predict now what will be the price of the fuel and in what way it will influence (negatively) technic-economical characteristics of the project. And you know that by discussing of the commercial use of any technology economical issues are among the most important ones.

Significant length of the active zone will also have a negative impact on the economy of the project. Long active zone will cause increasing of the total length of the reactor vessel. "Excessive" volumes of an expensive coolant, additional metal constructions, etc. will appear.

Next moment that provokes many questions is how can be achieved such a deep burnup (up to 40%) using a solid fuel? It is well known, that for the 10% burnup fuel should contain 10% of the hollow volume, of the porousness. What will remain from fuel if we are going to reach 40% burnup?

I would also add to what I have said in the previous passage, that nowadays there is no understanding if steel, that is used as a construction material of the fuel assemblies, will withstand those values of atom bias that will acompaign such a deep burnup.

This project of the lead-bismuth reactor proposes a reserve scheme of the fuel assembly - fuel is located not within the assembly, but on the outside of the tube. It means that the assembly construction has to provide upper and lower covers with the tubes welded in them. Appears a difference of the temperatures of the construction materials and difference of the temperature lengthenings, and compensation welds will be needed - for example, accordion boots, this will, for its turn, reduce the reliability of the whole assembly construction and will create a threat of its depressurization during the operation.

So without further engineering elaborations and additional researches it is difficult to judge about the perspectiveness of the conception of a lead-bismuth reactor working by the CANDLE scheme. Though, from the aesthetic point of view it looks very nice.

And in the conclusion I will add, that CANDLE is not a unique conception of this type. In our domestic industry such reactors have an informal name "reactors-selfeaters". Main difference of selfeaters is that after the first stage, where enrich uranium or plutonium are used, they start working with the infeed of natural or depleted uranium. Selfeaters don't need external power for the fuel cycle closing - they will produce and consume new fuel themselves.

SOURCE: AtomInfo.Ru

DATE: August 13, 2008

Topics: Russia, Lead-Bismuth, Japan